Article Sections:

- Introduction

- Getting Started

- Assembly

- Conclusion

Contents

Introduction

Being a sound engineer for rock bands, I’ve worked at hundreds of weddings and have always watched the photographers closely, even before I became one myself. The identifying trait of the wedding photographer seemed to be a flash bracket. This helpful device puts a powerful and portable light source above and (usually) to the left of the lens, with several benefits.

First, you get some minor shadows on the subject’s face, which adds a bit more depth to facial features. Not extreme, but much better than the flat and boring look from the pop-up flash many people seem to think is all you need.

The second reason to use a flash bracket is that by lifting the light source up and to one side, you eliminate the dreaded “red eye” effect that ruins so many snapshots and event photos.

If you’re out to purchase one, very basic commercial offerings start at around $13 and much better ones hang around the $40-60 range, but of course there are ultra-deluxe models that are in apartment rent range. As for me, I wasn’t thrilled with the idea of spending any kind of serious money for a tool that I might not use more than a handful of times each year – many other pieces of equipment are much higher on my list.

After doing some online investigation of the designs already available, I went with the DIY option and built my own flash bracket. Mine ended up costing me $5.11 but I had a few important parts already, so your mileage may vary.

Getting Started top

These were the following parts I used:

- Steel base plate – you need a strong piece of steel or aluminum that has holes for ¼”-20 wing screws. Make it yourself, or get lucky like me – mine came as an accessory for an old Sony F-1000 flash, and there are other similar ones out there.

- 1.15” thick Wood Dowel – approximately 7” in length cost me $4 from Home Depot

- Steel flash shoe – came from a plastic 35mm camera that wasn’t worth more than $5.

- 1 x ¾” anchor with (1/4”-20 thread)

- 2 x ¼”-20 wing screw bolts

We aren’t going to explore the various ways to connect a flash to your camera. There are too many variables that aren’t in the scope of this article. For mine I used a PC to Sunpak Cable – this came with my Sunpak 383 flashgun and a FS1100 Hotshoe Adapter for my Sony Alpha300.

Assembly top

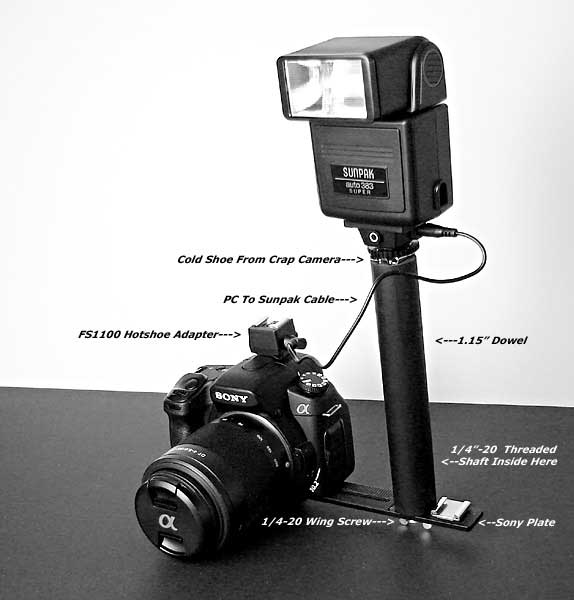

As shown in the photo/text above, there is a steel plate attached to my Sony Alpha300’s tripod screw hole that hosts a hardwood dowel, and on top of this is a flash shoe that holds my Sunpak 383 manual/auto flash.

1. For the base plate, you need a strong piece of steel or aluminum that has holes for two ¼”-20 wing screws at each end – one to screw into the camera’s tripod mount, and the other to secure the upright dowel.

2. The upright dowel was the most expensive part of this build, which was $4 from Home Depot. Make sure to cut it clean and straight and sand the ends so they are as close to 90 degrees as possible. I made mine around 7 inches long—no particular reason besides it just looked right to me.

3. Drill a hole into one end of the upright dowel to house the anchor for the wing screw – I used a ¾” anchor (1/4”-20 thread) but regretted not getting a longer one. To make up for this, I used my Dremel tool and cut the threaded section off a long ¼”-20 bolt and epoxied it into my anchor for added security and glue real estate inside the dowel.

Glue the anchor into your dowel, making sure it sits flush with the end. If it’s recessed even a tiny bit, tightening will stress the glue, and if the anchor sticks out there won’t be a flat surface meeting your mounting plate.

4. I obtained steel flash shoe came from a plastic 35mm camera that wasn’t worth more than $5. I used epoxy to affix the shoe to the top of the upright dowl, then added the screws that originally affixed it to the top of the camera.

Leaving the center contact on the donor camera makes this a coldshoe, technically. This means you can safely mount your flash without taping over anything for insulation. It’s very important to assemble the parts before mounting the shoe, otherwise it might not face the right direction.

There are also various hotshoes, coldshoes and similar adapters available at Adorama and B&H, or you could look for a cheap camera at yard sales and flea markets.

5. For cosmetics, I spray painted the upright dowel black. To achieve this, I put a long screw into the anchor which gave me a way to hold the dowel as I sprayed it, and then hung it up to dry.

6. To assemble, screw the base plate into your camera hot shoe, and the other wing screw into the upright dowel. Attach a flashgun to the hotshoe, and connect to the camera via your preferred method.

In Use top

The results are exactly as expected—zero red-eye when taking portrait shot directly head on. Additionally, there is a nice small catchlight in the pupil – no Photoshop required!

The two-piece design also makes it easy to slip it into a spare pocket inside my camera bag.

Conclusion top

In actual event use I’ve found that this DIY flash bracket design works well at fulfilling my goals of getting the flash far enough away from the lens to get rid of that “snapshot” look, while also being very inexpensive and more convenient to carry around in case it’s needed.

If I were a professional event photographer, it would probably be a big disappointment especially since there is no provision for flipping the flash over to shoot vertical compositions.

But for my casual needs it has already proven to be a great tool for getting my feet wet without spending too much money on a commercial product I might only use once or twice a year.

Be sure to check out our article on Putting Together a Budget DIY Photography Lighting System Kit for your Studio